Everything, Leather, Tutorials

2019 Year In Review

It’s a new year folks! How about we take a few moments and look back at what happened in the workshop in 2019.

In the beginning of the year I built a leather tooling table with an inset marble block. It turned into a slightly Frankenstein piece as I had to adapt and fix a few issues that came up. As they do say – hindsight is 20/20.

Tooling on this thing is now rock solid, the tools are all within easy reach, and I have a bit more storage underneath (here’s a link to an older all-around workbench tutorial I wrote). The tool rack shown was ultimately replaced by a leather strap that holds the tools against the wall. I learned the hard way that a sharp exposed knife held off the wall can make for a trip to the doctor for a few stitches!

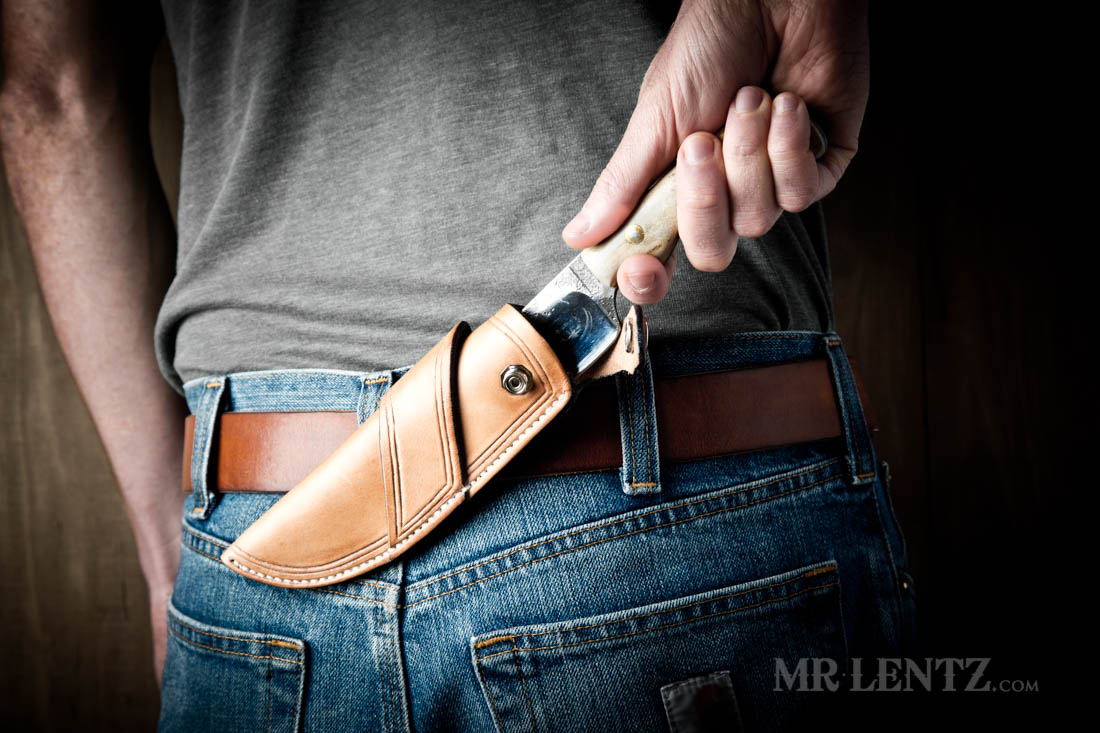

Every winter I tend to want to hole up and learn a few new skills, in 2019 that happened to be knife sheath building. The aim is to be able to offer custom fit sheaths to select customers sometime this year. Looks like I am just about ready to offer the service in a few months. If you are on my email newsletter you will receive notice and you can sign up here: Newsletter Signup.

Here’s a sheath tooled for my round knife. With a solid tooling bench you don’t have to worry about the tools jumping around on you when using the mallet.

Above is the completed round knife sheath, hand dipped into hot wax for the finish.

From there I started really experimenting and perfecting the hot-wax dipping method of applying both oil and wax to the leather sheaths for protection from the elements. It’s the same method used by leatherworkers in the old west and in my opinion it is a much better option for weatherproofing than any commercially available product. It is much more difficult to apply at first, but it’s also all-natural, lasts several times as long, and is easier to re-apply when needed. I plan to offer that style of finishing on future custom sheaths and leather goods.

I am always trying to find new and all-natural ways to work with leather. As it turns out, you can basically do it all without any commercial chemical. If you follow the old ways, it may take longer, but the results are stunning and come at no cost to the environment.

This sheath is a cross-draw and man was it a challenging piece to hand stitch. That’s almost an inch of leather in the middle!

The real fun of learning how to build a proper knife sheath is in all of the skills required to get through each step. You need sharp tools that hold an edge well, and you need to know how to sharpen them.

Ok Ok, enough about knife sheaths, what else happened in 2019?

I designed a few new Women’s wallets and purses for the shop. Above is the Phone Clutch that’ll securely fit most smartphones in the outside pocket.

Another new style is the Women’s Leather Wallet, designed to fit a ton of cards, unfolded cash and even some change in the small pouch. There’s a lot of high end leather in this wallet and it feels amazing to the touch.

An older cross-body purse was given a facelift. I changed the flap opening from a top open design to a more classic and longer front flap.

Several new cuff options also entered the shop – this one being a Triple Wrap Cuff. I cut them to three specific wrist sizes – 6, 6.5 and 7 inches.

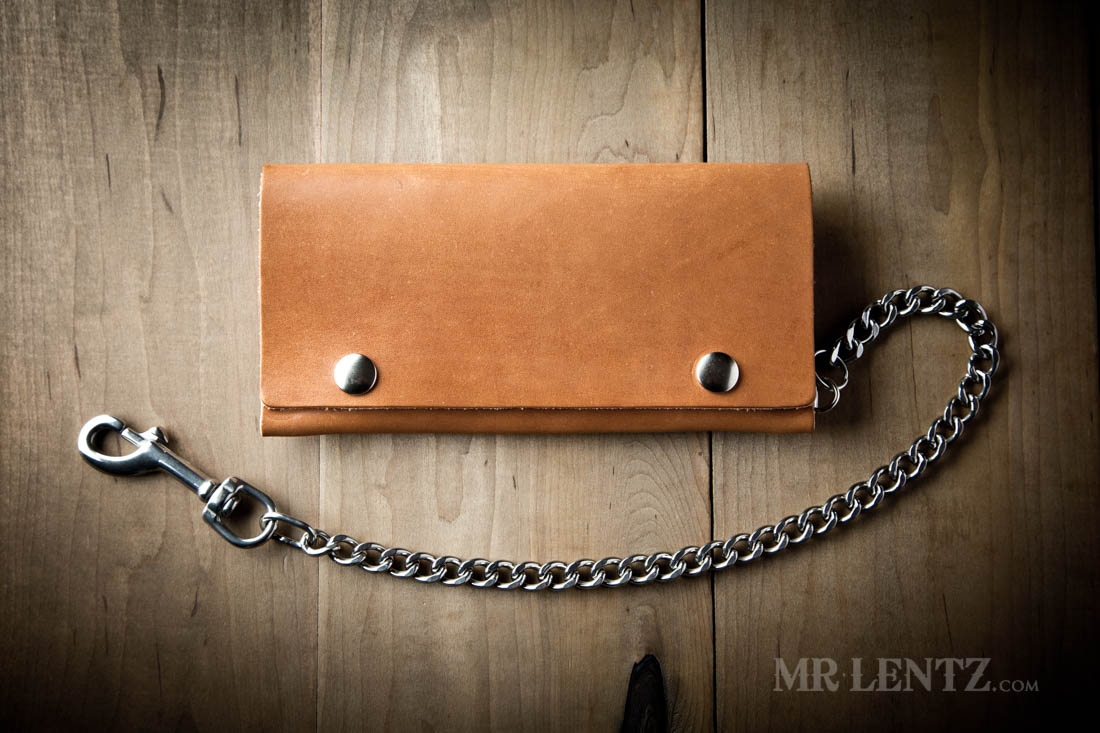

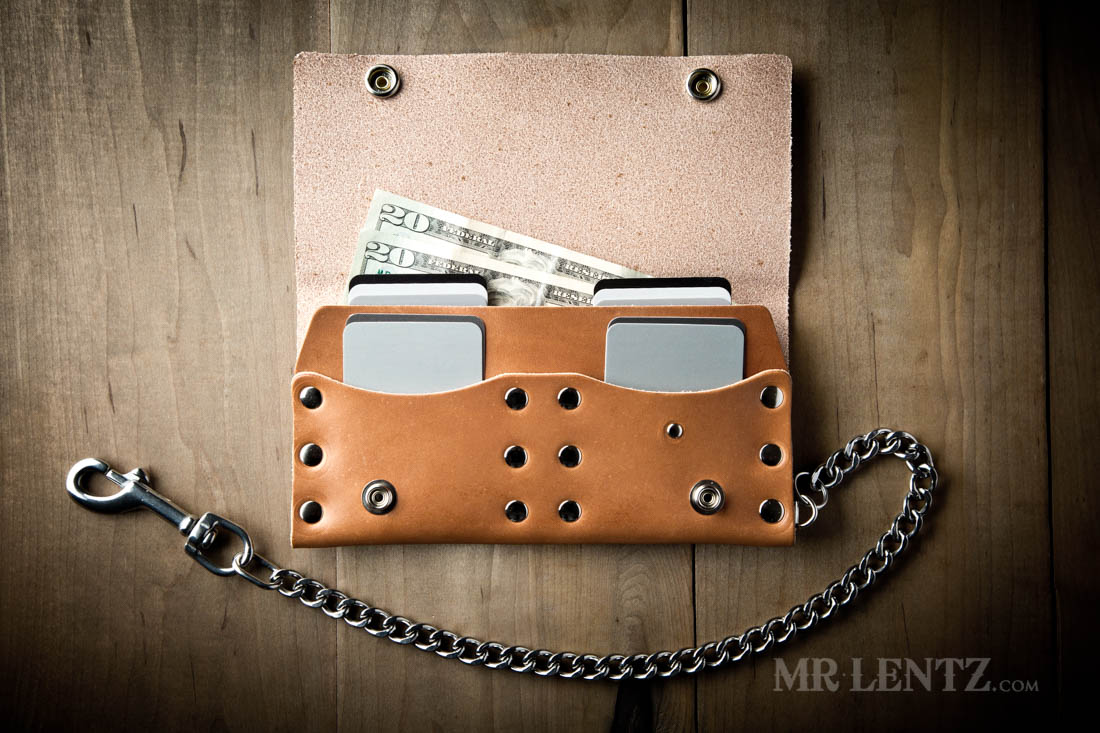

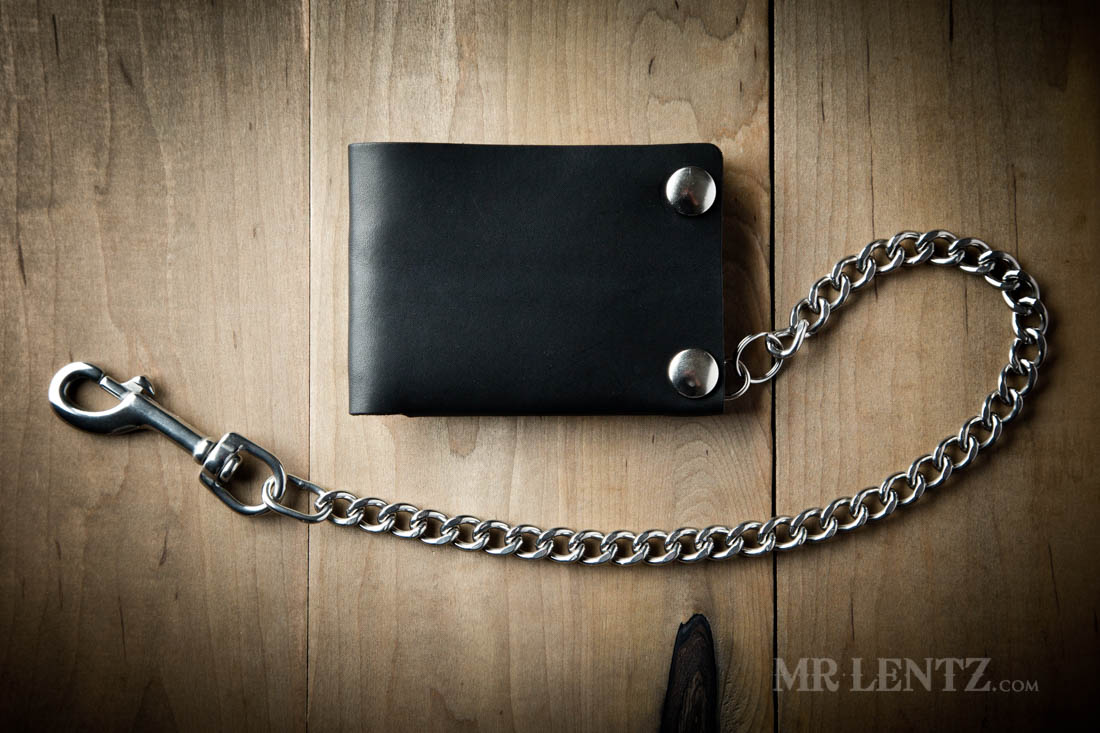

For all the dudes – I decided to finally work out the design for a Trucker Wallet. It’s one beefy wallet with thicker leather and a lot of carrying capacity.

It also has 5 chain options to choose from.

An update was made to the Mens Leather Wallet to now have the option for a snap closure system. I personally love this wallet with snaps, it has become my daily carry.

For all those out there with a Leatherman, I upgraded my previous design to fit most of the Leatherman branded tools. In addition you can choose from 5 different types of hardware finishes – one of which is the coveted Locking Snap.

Just for fun I made a cactus coaster set. I love cacti, from a distance. These are made from my extra thick belt leather, they are probably the only coasters out there made from this high quality of leather. Plans are in the works for a few more styles of coasters.

Our annual customer photo contest was a big hit this year with a record amount of entries. Every year I ask customers to send in photos of their leather goods from my shop. It’s fun to watch these things age and patina over time. The shot above is from Kayla P. showing off 48 months of use. Thanks Kayla!

For those aspiring leatherworkers out there I decided to completely revamp and organize the Tutorials section of my website. This is the area where you can find all sorts of great info on working with leather along with very detailed step by step photos.

A new tutorial also made it up finally – how to make a leather axe sheath. This is a very in depth tutorial about sheath making and includes over one hundred detailed shots of every step.

And what’s in store for the future?

Well, I am hoping to create several new tutorials this year. I have plans to design a handful of new products and on top of that…the shop will soon be opening to select custom orders. Yep – if you have an idea in mind and would like it custom built, I may be able to take on the project. The service may not come until late March though, so get ready.

Here’s to a fun and adventurous new year, thank you all for supporting my shop and being a fan!